Kiln Geezer - an Intermediate Technology Kiln

Abstract

An intermediate technology solution, a kiln design for firing ceramics and pottery in a more sustainable way.

Rational

Making pottery consumes large amounts of fuel and many countries have ceramics industries. Few are technologically advanced enough to manufacture high fired wares, like electrical insulators and sanitary wares. Countries whose ceramics industries are less developed have to import these products, at great expense. There are many reasons why high fired wares are not produced in places like north Africa, which has long traditions of ceramics production Some reasons are listed below in Table.1.

[1]

[1]

[2]

[2]

[3]

[3]

[4]

[4]

[5]

[5]

| Reason | Comment |

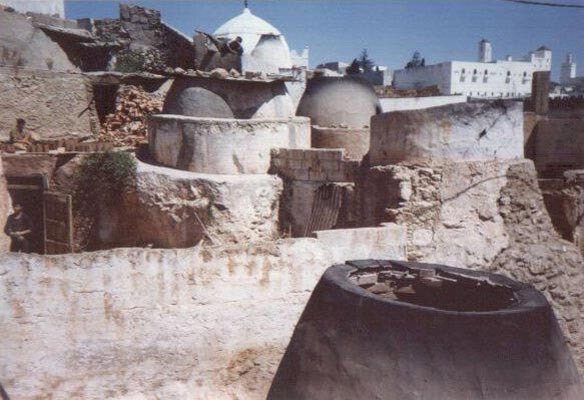

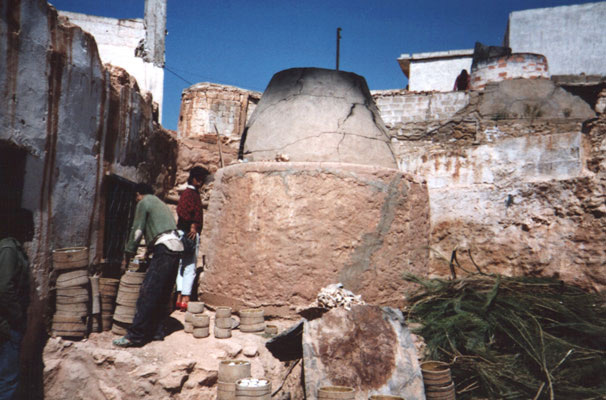

| Kiln design | Many countries still use the traditional up draught bottle kiln  [6] [6]  [7] [7]  [8] [8]

[9] [9]

[10] [10]

which wastes fuel because it doesn't retain heat well. It is quite likely that, even if more refractory clays were available, a temperature sufficient to vitrify the material would not be possible using the traditional kiln design. |

| Fuel available | Traditionally, plant material like wood and straw, or animal dung is used to fuel pottery kilns in countries where electricity and gas are not available. Palm fronds are used as the fuel for pottery kilns in Safi and Marrakesh, Morocco. The fronds have a high oil content and explode spectacularly when introduced into the fire mouth of a kiln. Along with the associated thermal shocks, there are also repeated ground tremors to affect the fragile wares stacked in a kiln. It is not unreasonable to assume that the impact of this firing method is detrimental to the quality of the end product. |

| Type of clay available | Traditionally, earthenware clay is used which has a porous body and often has inclusions like gypsum. A localised search to find a source of more refractory clays will require a high firing temperature capability in order to test the characteristics of the clay samples, ie; the temperature of vitrification, etc. |

| Traditional processes | The traditional process for removing unwanted materials like gypsum, is not thorough enough and consequently a high volume of wares are broken  [11] [11]  [12] and become flawed as a result from these inclusions. [12] and become flawed as a result from these inclusions. |

| Available knowledge | Traditional potteries are often family affairs and the specialist knowledge is handed down through the generations. Rarely do potters have a university education in ceramics, geology, mineralogy or chemistry. |

The Proposition

This document puts forward the proposition that by making some modifications to the traditional process of ceramics production, we create the potential for locally produced vitrified ceramic wares. Advantages to be gained by modifying the production process are bulleted below.

- Reduce the amount of fuel consumed when producing traditional pottery by using traditional fuels more efficiently.

- Better conserve the heat produced.

- Attain higher temperatures in order to fire more refractory clay bodies.

- Improve the clay extraction and refinement processes; remove gypsum and other inclusions, to improve the quality of the end product.

- Increase productivity by lowering the volume of wares which get damaged during a firing cycle.

- Encourage the use of fuel from sustainable sources.

- Reduce dependency on imports.

For more information Continue to

Kiln Geezer Page 2

While all works found on these pages may be freely reproduced for personal use, copyright does exists and the copyright owner must be consulted if you wish to use or reproduce the material for commercial purposes. [Disclaimer] In all cases higher quality files are available. To obtain these or for anything else - eMail the web host